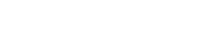

VEX200

Centrale de traitement d'air

VEX200

Centrale de traitement d'air

L’unité VEX200 est une unité de traitement de l'air rotative économe en énergie offrant une grande flexibilité grâce à différents types de roues, filtres et emplacements des raccordements.

VEX200

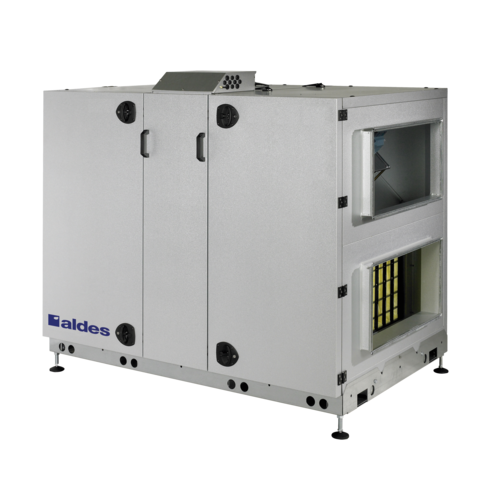

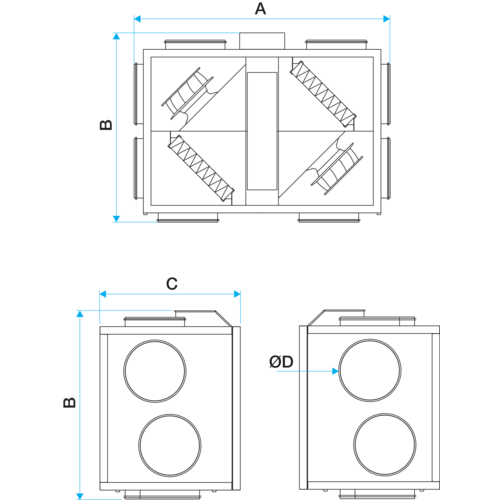

La VEX200 est économe en énergie grâce à un échangeur de chaleur rotatif et des moteurs EC. Deux types de rotor sont disponibles : standard et à haut rendement. Les nombreuses versions de la gamme VEX200 offrent une grande flexibilité d'installation et d'emplacement des raccordements : sur les côtés ou sur le dessus. La VEX200 est livrée avec des systèmes de commande intégrés, accessibles via le boîtier de raccordement à l'avant de l'unité. Aussi, la VEX200 est disponible en monobloc (VEX240-250) ou multibloc pour accéder à des espaces réduits (VEX260-280).

Les + produits

- Raccordement flexible – horizontal, vertical et inférieur,

- construction compacte pour petits espaces - multibloc en option,

- large choix d'options de filtres.

- Version intérieure et extérieure disponibles,

- qualité de l'air et confort thermique optimaux,

- très faible niveau sonore,

- économies d'énergie,

- installation et entretien faciles.

La VEX200 apporte de l'air neuf et filtré dans le bâtiment et récupère la chaleur de l'air extrait à l'aide de son échangeur de chaleur à haut rendement. L'air entrant peut être chauffé et/ou refroidi avec une gamme complète de batteries.

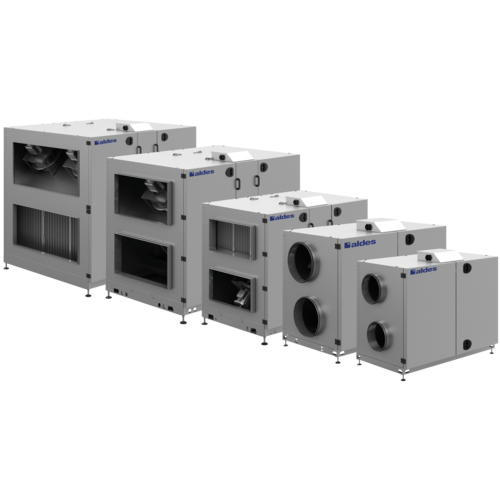

- L’option ALC™(Automatic Leakage Control : Contrôle Automatique des Fuites) est la solution brevetée qui prévient la propagation des virus par des centrales de traitement d’air à échangeur rotatif. Elle mesure, contrôle et ajuste en permanence la différence de pression entre les débits d'air soufflé et extrait afin d’assurer qu'aucun air contaminé ne recircule vers l'air propre de l'unité.

- Centrales monobloc ou multi-blocs selon modèle.

- Construction autoportante en panneaux double peau.

- Finition extérieure en Aluzinc AZ185 : classe de corrosion C4.

- Isolation par laine minérale 49 mm, (Classe A1 selon DIN4102), densité 65 kg/m³.

- Valeurs EN1886 : D2/, L2/L2, T2, TB3, F8, F9

- Piquages configurables.

- Moteur EC et roue à réaction haute performance EXstream

- Accès et entretien facile: composants montés sur glissières, régulation accessible par une trappe centrale spécifique.

- 2 choix d’efficacités sur échangeur rotatif (Eurovent AARE) avec zone de purge en option pour préserver la qualité d’air intérieure.

-

4 choix de types d’échangeur sur demande :

- standard aluminium à condensation,

- hygroscopique,

- sorption : idéal pour des climats chauds et humides,

- epoxy: idéal pour des ambiances corrosives (i.e. marin).

- Choix de filtres pour garantir la qualité d’air : filtres plan ou à poches M5 (ePM10 50%) et F7 (ePM1 65%) (nous consulter pour d’autres types de filtres et pré-filtres).

- Interrupteur intégré

-

Régulation EXact2 :

- vitesse constante,

- multi-vitesses,

- pression constante,

- 0-10 V.

-

Paramétrage et supervision via :

- commande déportée filaire,

- option : Webserver et communication GTB/GTC via protocoles Modbus RTU / RS485, BACnet MSTP / BACnet IP,

- option : Webserver et communication GTB/GTC via une passerelle fournie vers des protocoles Modbus TCPIP ou LON.

Traitement d'air pour les bâtiments tertiaires à haut rendement énergétique de tous types : bureaux, écoles, magasins, etc.

- Eligibilité au CEE : Oui

- N° de fiche CEE 1 : BAT-TH-126

Références produits et accessoires

Documents

Showing 1 - y of

document

-

VEX200 Documentation TechniqueDocumentations Technique & Commerciale2 Mo

-

VEX200/VEX300C Textes de prescriptionTextes de Prescription1 Mo

-

VEX200 - Déclaration CEConformités127 Ko

-

Télécommande IHM - Notice d'utilisationNotices4 Mo

-

VEX200 Notice d'installation électriqueNotices3 Mo

-

VEX200 Notice d'installationNotices2 Mo

-

VEX280 Guide de réparationNotices7 Mo