Caisson Piquage Acoustique et Aéraulique pour relevé d’étanchéité;CPT2A;Caisson Piquage Acoustique et Aéraulique pour relevé d’étanchéité galva;CPT2A galva;

Raccord

Caisson Piquage Acoustique et Aéraulique pour relevé d’étanchéité;CPT2A;Caisson Piquage Acoustique et Aéraulique pour relevé d’étanchéité galva;CPT2A galva;

Raccord

Le CPT2A assure la jonction et l'accessibilité du réseau collecteur vertical et du réseau horizontal en améliorant l'acoustique et l'aéraulique.

Caisson Piquage Acoustique et Aéraulique pour relevé d’étanchéité;CPT2A;Caisson Piquage Acoustique et Aéraulique pour relevé d’étanchéité galva;CPT2A galva;

Le caisson piquage (ou Té-souche) acoustique et aéraulique pour relevé d'étanchéité est un accessoire aéraulique en acier galvanisé qui permet de joindre le réseau collecteur vertical et le réseau horizontal tout en assurant, conformément aux exigences des DTU 68.1 et 68.2, l'accessibilité à la colonne verticale et au réseau horizontal. Il est spécifique aux colonnes débouchant en combles ou en terrasses des locaux tertiaires et des logements collectifs, pour lesquelles le relevé d'étanchéité est réalisé après la pose du caisson piquage. Le caisson piquage aéraulique et acoustique est équipé d'un jonc d'arrêt sur le corps du caisson pour maintenir le bouchon en position stable et ainsi limiter le risque de fuites. Les caractéristiques aérauliques du CPT2A diminuent la dépression nécessaire au ventilateur et donc peuvent permettre de choisir un ventilateur moins puissant, donc moins bruyant et moins consommateur d'énergie.

Les + produits

- CPT2A exclusif (brevet ALDES) : réduction de la consommation du ventilateur,

- 35% de pertes de charge en moins par rapport à un CPT standard,

- atténuation acoustique améliorée : 7dB (A) sur le bruit rayonné du ventilateur (3dB (A) de mieux qu'un CPT standard).

- gamme disponible du diamètre 125 au diamètre 500,

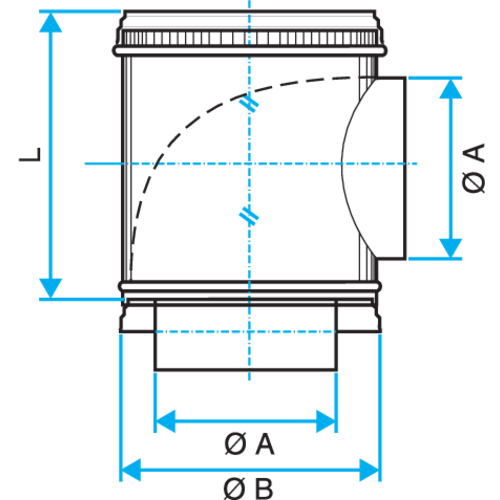

- Ø B - Ø A ≥ 100 mm permettant la réalisation du relevé d'étanchéité en terrasse,

-

performances du CPT2A par rapport au CPT standard :

- acoustique : mousse acoustique B-s1, d0 à haute atténuation (atténuation du bruit du ventilateur de 7dB (A), soit 3dB (A) de mieux qu'un CPT standard),

- aéraulique : déflecteur en tôle démontable sans aucun outil qui permet de réduire de 35% les pertes de charge, soit -7 Pa à 4 m/s.

- acier galvanisé conforme à la norme EN 10346 garantissant la régularité du revêtement,

- matériel conforme aux exigences du DTU 68.3 : 2013-06 P1-1 : "Installations de Ventilation Mécanique",

- classement au feu M0.

- facilité de montage des accessoires par emboîtage : les conduits sont femelles, les accessoires sont mâles,

- étanchéité à réaliser par l'ajout de mastic et/ou de bandes à trous,

- fixation avec le conduit à réaliser par vis autoforeuses (4 à 6 selon le diamètre),

- mise en oeuvre avec un Fourreau traversée de Terrasse : FT.

| Matériau principal | Matière de l'isolant |

|---|---|

| Acier galvanisé |

| Références | L (mm) | Ø A (mm) | Ø B (mm) | Poids (kg) |

|---|---|---|---|---|

| 11094860 - CPT 2A GALVA - D125/250 | 285 |

125 |

250 |

2,2 |

| 11094861 - CPT 2A GALVA - D160/315 | 320 |

160 |

315 |

3,1 |

| 11094862 - CPT 2A GALVA - D200/355 | 350 |

200 |

355 |

4,0 |

| 11094863 - CPT 2A GALVA - D250/400 | 400 |

250 |

400 |

5,9 |

| 11094864 - CPT 2A GALVA - D315/450 | 400 |

315 |

450 |

8,5 |

| Classement au feu |

|---|

| M0 |