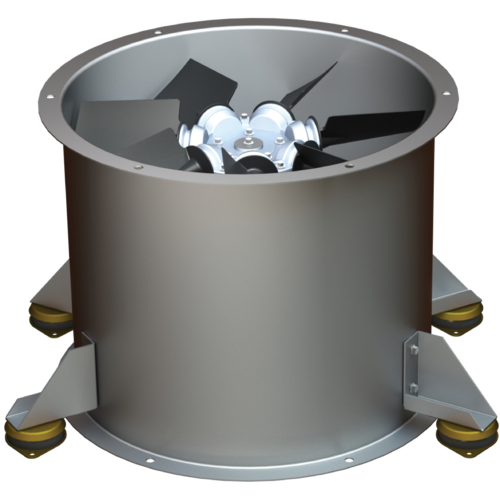

HELIONE Unclassified F200-F400

Axial fan

HELIONE Unclassified F200-F400

Axial fan

HELIONE is a range of axial smoke and heat exhaust fans rated F200-120, F400-120 or unclassified.

HELIONE Unclassified F200-F400

The standard HELIONE range varies from Ø 355 to Ø 1 250 mm and can reach airflows from 1,500 to 200,000 m3/h. HELIONE is used for ventilation and/or smoke and heat exhaust in residential areas (car parks, stairwells), non-residential premises (car parks, shops), and industrial buildings. It enables fresh air supply and exhaust as well as intermittent smoke and heat exhaust functions or in locations where acoustic limitations are not predominant. HELIONE combines with multiple accessories to assist its operation.

The + products

- range up to 128,000 m3/h,

- wide range for car parks, commercial and industrial premises,

- multiple accessories to facilitate operation.

HELIONE fan units require connection to the ventilation / smoke exhaust circuit to remove stale air and smoke to the outside.

They can be controlled by an AXONE safety box or a car park box.

-

compliance:

- certified F400-120 and F200-120,

- CE compliance: 1812-CPR-1623.

- Ø 355 to Ø 1250 mm, contact us for larger Ø.

- airflow from 1,500 to 120,000 m3/h with pressure values from 100 to 600 Pa,

-

impellers:

- comprise several aluminium blades,

- fitted on aluminium core,

- jet angle determined according to operating point.

- blades: individually X-rayed before assembly to ensure material quality,

-

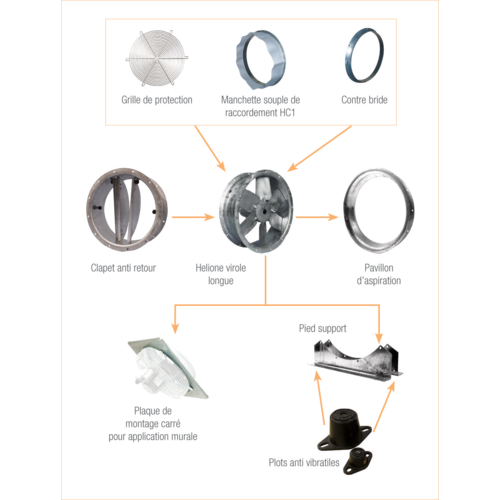

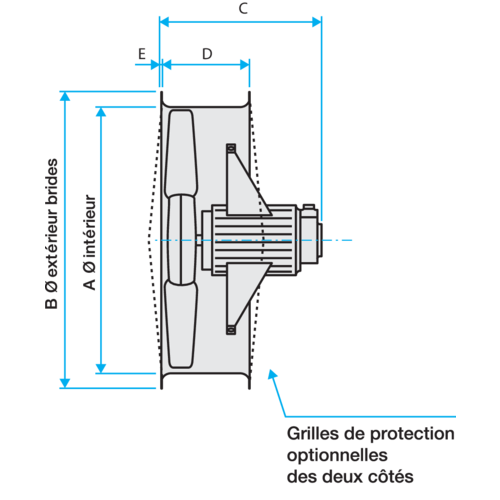

shells:

- formed from metal sheet,

- includes drilled rebate flanges for connections,

- standard = short ring, long ring optional.

- motor attachment arm: hot-dip galvanised for good corrosion resistance,

-

motors:

- bossed,

- 4 poles or 4/8 poles (2 poles on request),

- IP55, class F insulation as standard,

- operating temperature -20/50°C,

- 60 Hz motor: contact us.

-

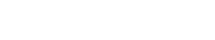

installation accessories:

- flexible sleeve,

- galvanised steel counter flange to attach Helione to a circular duct,

- galvanised steel square plate to attach Helione to a wall,

- galvanised steel support feet (x2) to fasten Helione,

- anti-vibration mountings (x4) to install under the support feet,

- non return damper: circular, two galvanised steel flaps,

- intake nozzle: improved air handling and acoustic performance.

-

electrical accessories:

- proximity switch,

- pressure switch,

- safety box ➡ see “AXONE micro II”.

- residential car park box

-

available options:

- long shell,

- gusset brackets for vertical installation,

- external pre-wired terminal block,

- protective finish for saline / aggressive environment: hot-dip galvanisation, epoxy powder paint, stainless steel.

-

horizontal on floor and against a wall, essential extras:

- square plate, anti-vibration mountings and feet, flanges and flexible sleeves or grille if not ducted.

-

horizontal on floor between two ducts, essential extras:

- anti-vibration mountings and feet, flanges and flexible sleeves for both sides, long ring for access to motor through access hatch.

-

horizontal against a wall, essential extras:

- reinforced square plate for attachment to wall, flange and flexible sleeve or grille if not ducted.

-

vertical suspended under slab or to duct, essential extras:

- protective screen if access possible or if risk of waste intake,

- long ring for access to motor if ducted on both sides,

- gusset bracket option.

- PV CE number : 1812-CPR-1623

ASSEMBLY MH OR HM:

-

horizontal on floor and against wall:

- essential options: economical square plate, feet and anti-vibration mountings, counter flanges and flexible sleeves or grille if not connected.

- horizontal on floor between two ducts:

- essential options; feet and anti-vibration mountings, counter flanges and flexible sleeves on both sides, long shell for access to motor through inspection hatch.

-

horizontal against wall:

- essential options: reinforced square plate for attachment to wall, counter flange and flexible sleeve or grille if not connected.

ASSEMBLY MHH, HMH, MHB OR HMB

-

vertical suspended under ceiling slab or to duct:

- the shell must be bolted in all holes of its flange.

- essential options: protective screen if access remains possible or if a risk of waste aspiration exists. If connected on both sides: long shell for access to motor through inspection hatch.

- for vertical installation, it is possible to add the gusset bracket option (consult

us).

- ducted on one side only, horizontal

use:

-

- grille on Motor side or Impeller side,

- Support feet,

- anti-vibration mountings,

- 1 counter flange,

The support feet are compatible with vertical installation.

- ducted on each side (long shell)

Use:

-

- support feet (if installed on floor),

- anti-vibration mountings,

- 2 flexible sleeves,

- 2 counter flanges.

- on structure with HELIONE short shell

use:

-

- support feet,

- anti-vibration mountings,

- flexible sleeves.

- Vertical installation on structure

Use:

-

- gusset option,

- anti-vibration mountings.

Products and accessories references

Documents

Showing 1 - y of

document

-

Certificate of consistency of performance CE - CPR / PV FEU /HELIONE® dual poleConformities5 MB

-

Declaration of performance (DOP) HELIONE® dual poleConformities122 KB

-

Conformity CMIM HELIONE®Conformities34 KB

-

HELIONE dual pole Non rated F200-F400 Installation & maintenance instructionsManuals1 MB